TAF Raised Access Floor Panel design combines the tensile strength of steel with the compressive strength of concrete to create the composite structure of a concrete slab. It’s the only panel designed specifically for use in the workplace. Conventional welded steel panels may be the right choice for equipment rooms, but they’re a noisy, flimsy feeling compromise for work environments. Walk on it one time, and you’ll know why TAF Floors are the only real choice for your requirements.

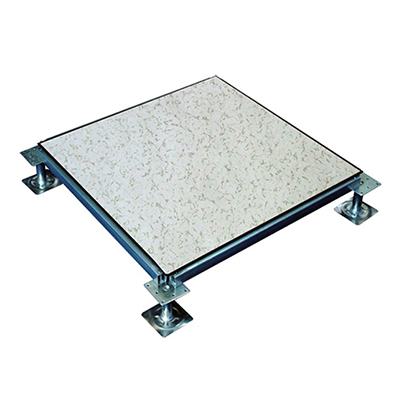

Typical Stringer Lay in System

Raised Access Floor Systems are modular, made up of tiles having size of 600mm x 600mm x 33mm and 600mm x 600mm x 35mm. Flat steel top sheet spot-welded to an embossed steel bottom sheet which are supported on a steel structure with different heights to achieve different levels. All raised floor panels are independent and identical which allows the exchange among themselves and get high durability and mechanical strength as well as access to the remaining space underneath. RAF systems are an effective solution in to manage space in organization. System like power, data, heating & cooling are easily manage in underfloor space as well as one can get minimum heat loss and improvement in indoor air quality. We can get more space and flexibility in infrastructure systems so that you can respond quickly and economically to organizational changes, expansion due to growth, adapting to new technologies and integrating new communication tools.

Access Floor System

Bare Finish Panel System

Bare Access Floors are constructed with a CRC Steel Top Sheet welded at 128 locations to the embossed bottom pan infilled with foaming cement. Top surface of this panels are normally coated with Epoxy base Powder.

The top steel plate and bottom steel plate are spot-welded to form a high quality shell, after which this shell is cut to size 600x600mm. The Shell is treated by phosphating and painted with powder coating and at high pressure light weight and non-combustible foaming cement compound is injected to inner empty core of panel ensuring that there are no air gaps left behind. After curing, the structure will be stable and strong to support the designed loading capacity. The bare access floor panel has high strength and high durability. One can achieve better acoustic and no squeaking sound due to low minimum – maximum gap between panels. Bare Panel System are also helpful for places where there are height constraints, and can be fixed at a minimum height of 4 inch. Bare panel systems have an advantage of covering the top surface finish with different options like Wood Planks, Carpets, Vitrified Tiles etc to match corporate themes and interiors.

Application

Used for Computer Room, Data Centre and Communication Centre, Exhibition Centre, Auditoriums and Showrooms.

HPL / Vinyl Finish Panel System

HPL stands for “High Pressure Laminate”. Because the top layer of HPL consists of several separate layers of pressed melamine, it is shock resistant and thus more resistant to falling objects/damage than other types of laminate (DPL, CPL and DLP). HPL finishes are laminated to the top face of the panel before being trimmed and edged ready for rapid installation on site.

The tough and elasticphenol core makes the material impact resistant. These characteristics are associated with a high degree of chemical resistance and high heat resistance. HPL dissipates static and provides an easy to clean and maintain walking surface.

Application

HUB Rooms, Server Rooms, Electrical Rooms, UPS Rooms, Data Centers, Control Rooms, Control Rooms.

Vitrified Panel System

- 600 mm x 600 mm all Steel welded construction with an enclosed bottom pan of 49 hemispherical cones and 36 reverse cones

- The Bottom pan subjected to pre-treatment along with 40 – 60 micron epoxy coating to achieve corrosion resistance

- Vitrified tile is stuck on to the bottom pan

- Inner empty core of the Panel is injected with a light weight, non-combustible cementitious compound at high pressure

- Technology enhances the strength and durability of the system while reducing the risk of damage during transportation, handling and installation

- A 10 mm thick premium quality decorative vitrified flooring is fixed to the top of the embossed bottom pan with adhesive of approved quality. The Vitrified tile shall have a slope of 5 degrees and be stuck on all four sides with 1 mm PVC edge band.

- System available in TAF 1500 Grade

Application

Cafeteria/Pantry, Showrooms, Lecture Halls, Exhibition Halls.

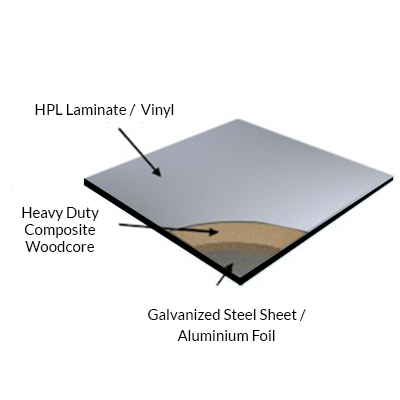

Wood Core Panel System

Made of high density chip board, our wood core panels offer a reliable and stable flooring system. The bottom of the 600mm x 600mm x 35mm particle board glued to galvanized steel or aluminum foil at bottom. Woodcore Panel Systems are available with Top Surfaces of either antistatic HPL /ESD vinyl /Vitrified Tile. The edge of the panel is protected with conductive PVC coating to prevent panels from moisture and damage. Due to its low weight characteristics and easiness in installation. It is suggested as an ideal solution for large installations.

TAF ACCESS FLOORS – SELECTION GUIDE

| Grade | Concentrated Load Kg (lbf) | Ultimate Concentrated Load Kg (lbf) | Uniform Distributed Load Kg/Sqmt (lbf/sqft) | Rolling Load Kg (lbf) | Pedestal Axial loading kgs (lbf) | |

| Common Used System | TAF 800 | 362 (800) | 905 (2000) | 1400 (289) | 190 (420) | 2200 (4840) |

| TAF 1000 | 453 (1000) | 1135 (2500) | 1650 (340) | 225 (500) | 2200 (4840) | |

| Heavy Duty | TAF 1250 | 566 (1250) | 1415 (3200) | 1900 (390) | 280 (590) | 2200 (4840) |

| TAF 1500 | 680 (1500) | 1700 (3750) | 2150 (440) | 315 (690) | 2200 (4840) |

©2018 TAF Floors & Ceilings | Made with ❤ at ChimpLab